SWESTEP was invited to VESTFORBRÆNDING in Copenhagen to talk about plastic waste

SWESTEP see plastic waste as a valuable feedstock that can be processed into sustainable fuels and energy, or also as a chemical raw materials to refine into performing chemicals for the fossil-dependent industry.

CEO Karl Magnus Mattsson’s speech on how SWESTEP’s Catalytic Conversion technology recycles plastic waste in an both economic and environmental viable way led to many questions and interesting dialogues.

VESTFORBRÆNDING is Denmark’s largest waste management company.

Each year VESTFORBRÆNDING handle around 1 million tonnes of waste and the focus is on the resource value of the waste – whether it is materials for recycling or fuel for energy production.

SWESTEP sees this as a interesting and rewarding first step and looks forward to the next step.

Picture above – Some of the participants from the meeting;

Henric Jacobsen – VESTFORBRÆNDING

Nana Winkler – DANSK AVFALDSFORENING

Martin Porsgaard – NISA (Nordic Initiative for Sustainable Aviation)

Anders Kiil – VESTFORBRÆNDING

Svend Søyland – NER, Nordic Energy Research and Martin Porsgaard – NISA, Nordic Initiative for Sustainable Aviation

Workshop on “Sustainable Aviation Fuels” at Nordens Hus in Copenhagen.

Aviation stakeholders gathered to discuss the prospects of a sustainable future for jet fuels.

SWESTEP was invited as speaker, at the premises of Nordic Council of Ministers in Copenhagen, together with decision makers, politicians and representatives from SAS, Airbus, Boing, Preem and BP to mention but a few.

The workshop was organized by NISA, Nordic Initiative for Sustainable Aviation, DTU-Chemical and Biochemical Engineering and NER, Nordic Energy Research

There was widespread agreement among the presenters that the time had come to make a serious push forward in adopting sustainable aviation fuels on a large scale. But the stakeholders also acknowledged that there are a number of challenges in this. The price and availability of biofuels remain prohibitive for large-scale adoption in aviation, and there is still a lack of strong political framework in many areas. Ensuring that the supply chain for biofuel production is genuinely sustainable will also need to be addressed. However, despite these challenges, the workshop made clear that there is strong will on the part of aviation stakeholders to adopt biofuels on a much larger scale than exists today.

The subject this day primarily focused on the Nordic Market, and what must be done to make Aviation more sustainable, renewable and viable.

The main points discussed and lively debated also during the breaks were;

• Requirements for clearer regulations and guidelines from decision makers.

• It is necessary with investments in new green fuels, initially as blend in and in the long run highlight new fuels that are completely fossil free.

• A central issue was a price on CO2 emissions and how this could be financed, where most of the participants agreed that this is a necessary way.

• Last but not least (time factor) of today’s aircraft fleet, we must be aware that conversion will take at least 20-25 years.

JP Morgan Friberg presented SWESTEP process technology, highlighting the importance of providing flexibility from the feedstock perspective in order to produce and deliver volumes of renewable fuels that meet the demands and qualities of the market.

SWESTEP ended by inviting relevant stakeholders to a Joint Test Run with the purpose of offering the participants an opportunity to conduct tests, evaluate and see in which way SWESTEP could become a future supplier of renewable fuel products.

For more information – Link to the Nordic Energy Research

JP Morgan Friberg in dialogue with Maria

Wetterstrand – Appointed by the Swedish

Government to investigate sustainable

biofuels for aviation

Photo by – Christian Ove Carlsson

Giving plastic waste a new life

People all over the world are throwing out large quantities of plastic each year, representing a huge sustainability issue.

Over the past year, the Swedish green tech company has been working closely with EIT Climate-KIC and the City of Copenhagen to carry out a feasibility study on the conversion of plastic waste to new sustainable oil. Since being established in 2012, SWESTEP has been developing an industrial process capable of turning all hydrocarbon-based waste and residues, such as plastic, into renewable fractions. In practical terms, this means that any organic waste stream can be considered as a feedstock, and duly be transformed into a wide range of renewable fuels or useful sustainable liquids and materials to be used again.

In theory, this process could have huge implications for how we deal with plastics, as well as waste management in general, as it could lead to the establishment of major circular economy loops into a city’s ecosystem, provide new sources of renewable energy, and create new revenues and jobs—effectively converting what was previously considered waste into a resource. One key aspect of SWESTEP’s technology is that the feedstock doesn’t require separating prior to processing, meaning mixed waste streams are just as effectively processed as sorted ones. This contrasts wildly with the status quo, in which mixed waste streams require appropriately sorting before the separate elements can be recycled.

Creating industrial inputs from waste plastic for industries that typically require fossil-based fuels or petrochemicals for major parts of their operations doesn’t just represent a welcome remedy to the problem of municipal waste, it also embodies potential to reduce the consumption of fossil-fuels and thus, contributes to climate change mitigation.

Given what was on offer, it’s easy to understand why Copenhagen was interested in a potential collaboration. Per Boesgaard, coordinator of the city’s Climate Plan 2025, had this to say:

‘Waste management, and particularly plastic waste management, has represented a huge problem for the city for a long time. Plastic is now a large part of people’s daily lives, yet it represents a huge environmental problem with regards to both the consequences of its disposal and its carbon footprint.

Our challenge [as the City of Copenhagen] is to manage this problem holistically, which means solving the environmental issues without disrupting the day-to-day of our citizens. Thus, participating in projects such as this and collaborating with pioneering companies like SWESTEP to investigate the potential of their technology is both necessary and exciting for us as a city. We are very pleased with the outcome of this project and look forward to working more with SWESTEP and Climate-KIC in the future.’

In July 2016, the City of Copenhagen, SWESTEP, NISA, Copenhagen Airports, and other partners, took part in “Trash to Cash” an EIT Climate-KIC Pathfinder project aiming to confirm if their “turnkey technology” can make a positive impact to the city’s plastic waste challenge. After testing the process on a batch composed of plastic and biomass, the feasibility study confirmed that both the feedstock, the technology, and the process were viable. Karl-Magnus, CEO of SWESTEP, had this to say about the process:

‘I am delighted with the results because we can now show that SWESTEP can use our process to recycle a mixed organic MSW feedstock that includes plastics. We already are planning for further tests on other special feedstocks to evaluate their economic potential.

The outputs of the process can be used as an environmentally sound substitute for fossil fuels and thus, the municipality waste can end up being recycled into a whole range of things, such as new textiles, new plastics, medicines, renewable diesel, and jet-fuel. I am also proud that we have proved we can make a difference in waste management processes whilst also being an asset to the energy sector. Through our process, we can create new jobs, new industries, and new revenue streams for the city municipalities—all in an environmentally and climate-friendly way.’

Martin Poesgaard, Director of NISA, the Nordic Initiative for Sustainable Aviation is optimistic about the process: ‘With the results of this feasibility study we can see that it is possible to convert the waste plastic residues to a new oil. We [at NISA] find it quite remarkable as it occurs at relatively low temperature and without pressure setting. Our hope is that the oil produced can be further processed into a sustainable jet fuel as if possible, this could represent a major breakthrough in our efforts to make the aviation industry more sustainable.’

SWESTEP will now proceed with additional documentation and analysis of the technology and the end products. Now, the goal is to find industrial partners and investors as well as involvement from the public and the government. SWESTEP is very optimistic about this and sees the solution as an important and low-cost contribution to the circular economy and environmental improvements.

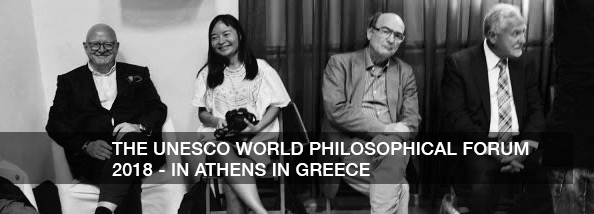

News from World Philosophical Forum

– Athens in Greece

Karl Magnus Mattsson, Founder and CEO of SWESTEP, was one of the speaker at this years World Philosophical Forum.

His speech addressed the world’s sustainability goals, the emissions and pollution problem, and the possibility using waste as raw material to produce renewable fuels, energy and sustainable liquids, that ultimately could replace our fossil dependence.

He gave facts, statistics and figures on population growth, oil prices, emission allowances and how our oceans and mother earth is being raped by waste and that we must put an end to this now!

He concludes his speech by adressering coming generations.

Karl Magnus Mattsson receives honorary award for

his work for the organization and commitment for

sustainable climate smart solutions

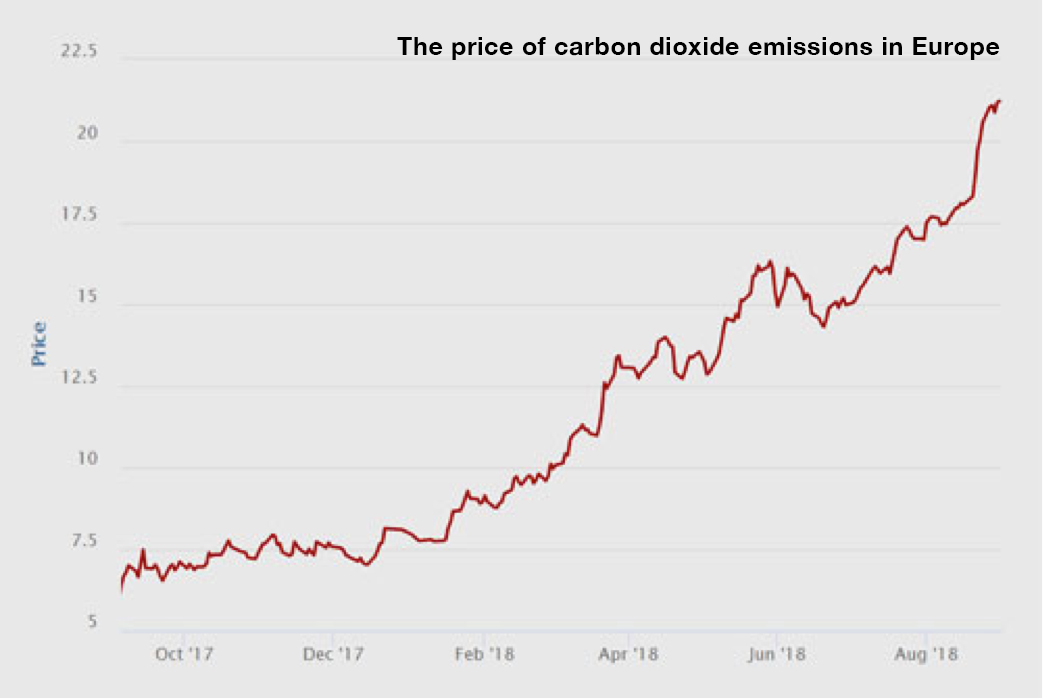

The price of emission allowances for carbon dioxide rises to the skies

In August, the price of emission allowances has risen to over 21 dollars per ton, the highest level of a decade.

The EU Emissions Trading Scheme is an instrument for cost-effective reduction of greenhouse gas emissions. The system is based on common EU rules, covering all member states and Norway, Iceland and Liechtenstein. EU emissions trading began in 2005. Since its inception, the system has been expanded step by step and now applies to more industries.

Today, some 13,000 European facilities are included in the system, of which about 750 are in Sweden. Many facilities are located in energy-intensive industry and energy production.

The trading system has received a lot of criticism over the years but now it seems that Europe finally got it.

During the third week of August, the price of emission rights to over 20 dollars per ton, the highest level in a decade.

But not only that. Costs to generate electricity from both coal and gas have also risen sharply since the beginning of 2017, not least because the price of imported coal and gas has risen.

The cost of generating electricity from coal has risen by 72 percent to 46 euros per MWh and the equivalent for gas is 43 percent to 49 euros per MWh.

An analysis by Berenberg Bank argues that the shortage of allowances will be able to drive the price up to 100 euros per ton by 2020.

Source / Link – Veckans Affärer (Article in Swedish)

Meeting with Norrecco in Copenhagen Denmark

Positive signals from meeting with Norrecco. The dialogue is now entering the next phase of setting up SWESTEP Installations in Denmark.

Norrecco’s interest lies in strengthening its positioning in the Danish Recycling Market, through the ability to offer a more sustainable and viable alternative, especially in the field of plastic recycling.

The first step is to look at setting up a SWESTEP Plant in Copenhagen Harbor.

Karl Magnus Mattsson – SWESTEP

Søren Eriksen – Norrecco

Martin Porsgaard – NISA

Karsten Ludvigsen – Norrecco

NEWS from – European Biomass Industry Association

Read article under (LINK), but first!

YES, Biomass has an important part in the circular economy, but

we must focus on solutions where we recycle, process and refine

the residues. The agriculture and forestry sector, in fact the food

industry as a whole has an important role to play.

All types of cultivable farmland must eventually be allocated for

sustainable food production. Using this kind of valuable land for

producing raw material/feedstock for energy or new raw materials

for the production of consumer goods is not defensible.

And from a climate perspective, with regard to emissions footprint,

it is a scandal to ship this raw material around the world for production

of renewable energy or fuel production.

In order to achieve a sustainable balance, where we can free ourselves

from the fossil dependence, both viewed from the circular economy and

the CO2 neutral economy, we must act regionally in a responsible way.

The global economy has both its pros and cons, so to offer a viable solution,

it is essential that all steps work regionally/locally: – (1) Raw Materials,

(2) Processing, (3) Production, (4) Consumption/Use.

The ability to combine and mix all types of hydrocarbon based waste, with

biomass as raw material / feedstock, is optimal, and a must in order to meet

market demands and future regulations.

The SWESTEP Plants that can simultaneously handle mix and recycle most

organic waste, including plastics, with biomass.

Add also the flexibility, size and option in regard to: (1) Input Materials,

(2) Production Unit (3) End Products, and you have a product, solution and

company with growth potential that is both viable from an economic and

environmental perspective.

SOURCE & PHOTO – European Biomass Industry Association

Trash to cash: How SWESTEP gives plastic waste a new life

People all over the world are throwing out large quantities of plastic each year, representing a huge sustainability issue. SWESTEP aims to address this by converting household plastic waste into sustainable oil and new plastic raw materials.

Over the past year, the Swedish green tech company has been working closely with Climate-KIC and the City of Copenhagen to carry out a feasibility study on the conversion of plastic waste to new sustainable oil. Since being established in 2012, SWESTEP has been developing an industrial process capable of turning all hydrocarbon-based waste and residues, such as plastic, into renewable fractions. In practical terms, this means that any organic waste stream can be considered as a feedstock, and duly be transformed into a wide range of renewable fuels or useful sustainable liquids and materials to be used again.

In theory, this process could have huge implications for how we deal with plastics, as well as waste management in general, as it could lead to the establishment of major circular economy loops into a city’s ecosystem, provide new sources of renewable energy, and create new revenues and jobs—effectively converting what was previously considered waste into a resource. One key aspect of SWESTEP’s technology is that the feedstock doesn’t require separating prior to processing, meaning mixed waste streams are just as effectively processed as sorted ones. This contrasts wildly with the status quo, in which mixed waste streams require appropriately sorting before the separate elements can be recycled.

Creating industrial inputs from waste plastic for industries that typically require fossil-based fuels or petrochemicals for major parts of their operations doesn’t just represent a welcome remedy to the problem of municipal waste, it also embodies potential to reduce the consumption of fossil-fuels and thus, contributes to climate change mitigation.

Given what was on offer, it’s easy to understand why Copenhagen was interested in a potential collaboration. Per Boesgaard, coordinator of the city’s Climate Plan 2025, had this to say:

“Waste management, and particularly plastic waste management, has represented a huge problem for the city for a long time. Plastic is now a large part of people’s daily lives, yet it represents a huge environmental problem with regards to both the consequences of its disposal and its carbon footprint.

Our challenge [as the City of Copenhagen] is to manage this problem holistically, which means solving the environmental issues without disrupting the day-to-day of our citizens. Thus, participating in projects such as this and collaborating with pioneering companies like SWESTEP to investigate the potential of their technology is both necessary and exciting for us as a city. We are very pleased with the outcome of this project and look forward to working more with SWESTEP and Climate-KIC in the future”.

Source DAILY PLANET; Read the full article – click here

Wasted Health: Pollution is Killing Millions

Two years after ISWA’s Report “Wasted Health: The tragic case of dumpsites” that described the linkages between the world’s dumpsites and human health, a new landmark report that was published recently by the Lancet Commission on Pollution and Health reveals that pollution kills at least nine million people and costs trillions of dollars every year. This report stems from the most comprehensive global analysis to date,

and warns the crisis “threatens the continuing survival of human societies”.

A comparison of the two reports reveals important common conclusions and concepts, highlighting that the health impacts of pollution, as well as the health impacts of dumpsites, remain rather underestimated.

Both reports concluded that the assessed health impacts are probably the minimum ones that can be estimated with very conservative assumptions.

Parallels Between Lancet Commission on pollution and health and ISWA’s Wasted Health

The new report estimates that diseases caused by pollution were responsible for an estimated 9 million premature deaths in 2015—16% of all deaths worldwide — a staggering number and three times more deaths than from AIDS, tuberculosis, and malaria combined and 15 times more than from all wars and other forms of violence. In the most severely affected countries, pollution-related disease is responsible for more than one death in four…

Source ISWA NEWS; Read the full article – click here

SWESTEP Plastic to Liquid to Plastic Recycling

People all over the world are throwing out large quantities of plastic each year, representing a huge sustainability issue. SWESTEP aims to address this by converting household plastic waste into sustainable oil and new plastic raw materials.

Over the past year, the Swedish green tech company has been working closely with Climate-KIC and the City of Copenhagen to carry out a feasibility study on the conversion of plastic waste to new sustainable oil. SWESTEP havedeveloped an industrial process capable of turning all hydrocarbon-based waste and residues, including plastic, into renewable fractions. In practical terms, this means that any organic waste stream can be considered as a feedstock, and duly be transformed into a wide range of renewable fuels or useful sustainable oil/liquids to be used again.

In theory, this process could have huge implications for how we deal with plastics, as well as waste management in general, as it could lead to the establishment of major circular economy loops into a city’s ecosystem, provide new sources of renewable energy, and create new revenues and jobs—effectively converting what was previously considered waste into a resource. One key aspect of SWESTEP’s technology is that it can mixe waste streams simultaneously just as effectively processed as sorted ones. This contrasts wildly with the status quo, in which mixed waste streams require appropriately sorting before the separate input material can be recycled.

Creating industrial inputs from waste plastic for industries that typically require fossil-based fuels or petrochemicals for major parts of their operations doesn’t just represent a welcome remedy to the problem of municipal waste, it also embodies potential to reduce the consumption of fossil-fuels and thus, contributes to climate change mitigation.

Source – Polyestertime, read full article here