SWESTEP – Chemical Transformation and Recycling Technology Boosts Corporate ESG Development

SOURCE; Link to original article from United Daily News in Taiwan

In the era of carbonomics, experts predict that carbon will become the third currency of the market, in addition to the US dollar and the Chinese yuan. Mr. Huang Jieping, CEO of Greatech Technology, said that Sweden has the highest carbon tax in the world, up to 122 euros per ton, which puts huge pressure on enterprises but also cultivates world-class carbon reduction capabilities. Greatech has introduced SWESTEP’s sustainable technology of chemical transformation and recycling from Sweden to help enterprises promote ESG (Environmental, Social, and Governance).

Greenhouse gases mainly come from fossil fuels, and coal combustion emits a large amount of carbon. Converting coal into oil is a good idea, but the cost of producing clean coal is too high. Data shows that Taiwan’s annual carbon emissions are about 280 million tons, of which Formosa Petrochemical Corporation alone accounts for 25 million tons, and with the affiliated companies in the group, the total accounts for nearly 20%. Although Yunlin County’s income is not high, its carbon emissions are not small, and Mailiao bears a significant responsibility. Groups such as Formosa Plastics, Uni-President, Evergreen, and China Steel actively seek carbon reduction solutions, and all have shown interest in SWESTEP and are carefully evaluating it.

SWESTEP can recombine the carbon and hydrogen molecules of seven recycled plastics into hydrocarbon bonds, producing naphtha oil that is similar to crude oil and can be further processed into chemicals such as ethylene. The conversion rate of SWESTEP is 85%, and the production cost of 1 liter of synthetic biodiesel is 0.5 euros, which can be as low as 0.3 euros for large-scale equipment. The residual 3% mineral salt residue can be used as fertilizer, achieving true zero-waste circular economy. One liter of this type of biodiesel can generate 5-10 degrees of electricity, and the cost of electricity generation per degree is even lower than nuclear energy, Huang Jieping said.

Large carbon emitters and the capital market are highly interested in SWESTEP. SWESTEP’s fully automated pre-processing process consists of 11 procedures and can run 24 hours a day. With a total cost of 20 million euros (about 660 million Taiwan dollars) for the complete set of equipment in the middle and later stages, the equipment can produce 1 ton of diesel per hour, and the estimated IRR of small and large equipment is 29% and 45%, respectively, with a recovery period of 5.5 years or 3.5 years. The negative pressure smokeless chimney equipment covers an area of 200 pings, including a total of 1,500 pings in the surrounding area. Compared with incinerators, it occupies several hectares of land. In Penghu, with a daily garbage output of 72 tons, only one set of equipment is needed.

Energy independence and security are crucial for island economies, and Taiwan is no exception. In the early stage, Greatech Technology aimed at Penghu and used SWESTEP to achieve a low-carbon island. The main benefits come not only from the processing fee but also from the renewable energy and carbon credits generated. Huang Jieping said that Japan exports technology and funds to Myanmar and the world through the Joint Crediting Mechanism (JCM) of carbon credits, following this model. There are more than 50,000 islands around the world, and international funds, including Saudi Arabia’s basic industry, are optimistic. Japanese venture capital, H & Q Asia Pacific, which was approved by the National Development Council at the end of last year, are sharpening their swords.

Mr. Huang Jieping together with Petter Sund, General Manager of Taiwan and Director of the Business Division of the Swedish Trade and Investment Council, at the Taiwan-EU Electric Vehicle Supply Chain Investment Cooperation Forum last year.

SOURCE; Link to original article from United Daily News in Taiwan

JP Morgan Friberg represented Swestep as speaker in Panaji, Goa India at the conference “URBAN SUSTAINABLE and SMART CITY EVENT”, where waste management was high on the agenda.

The conference was interesting, uplifting and productive, among the participants were decision-making politicians, university and several companies in the private sector working with waste management, infrastructure and urban planning.

INFORMATION – The Urban Sustainability and Smart City (USSC)

The USSC Event is a series of 4 events conducted under the India – EU Urban Partnership (IEUP), a project between the Ministry of Housing and Urban Affairs, Government of India, and the European Union, to support the implementation of smart, resilient and sustainable urban development in India.

On the agenda on the USSC Event was; developments in the areas of mobility, solid waste management and urban resilience. The event was facilitated by the AETS-IEUP project team over two days and have participants from the public and private sector from India and the EU.

LINK to EU News

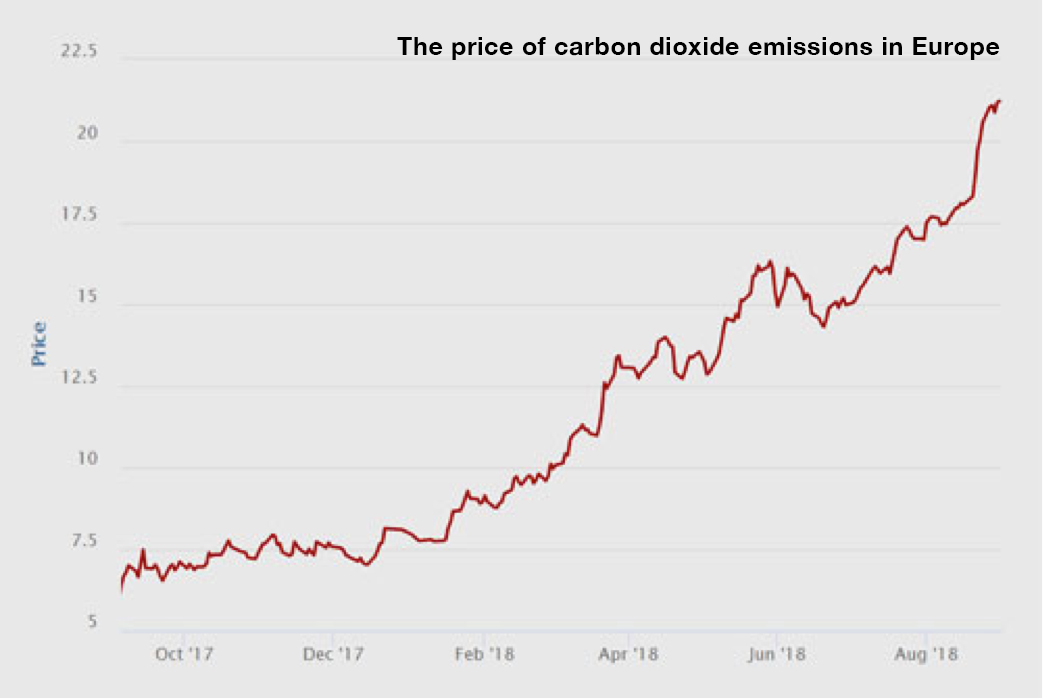

The price of emission allowances for carbon dioxide rises to the skies

In August, the price of emission allowances has risen to over 21 dollars per ton, the highest level of a decade.

The EU Emissions Trading Scheme is an instrument for cost-effective reduction of greenhouse gas emissions. The system is based on common EU rules, covering all member states and Norway, Iceland and Liechtenstein. EU emissions trading began in 2005. Since its inception, the system has been expanded step by step and now applies to more industries.

Today, some 13,000 European facilities are included in the system, of which about 750 are in Sweden. Many facilities are located in energy-intensive industry and energy production.

The trading system has received a lot of criticism over the years but now it seems that Europe finally got it.

During the third week of August, the price of emission rights to over 20 dollars per ton, the highest level in a decade.

But not only that. Costs to generate electricity from both coal and gas have also risen sharply since the beginning of 2017, not least because the price of imported coal and gas has risen.

The cost of generating electricity from coal has risen by 72 percent to 46 euros per MWh and the equivalent for gas is 43 percent to 49 euros per MWh.

An analysis by Berenberg Bank argues that the shortage of allowances will be able to drive the price up to 100 euros per ton by 2020.

Source / Link – Veckans Affärer (Article in Swedish)

Meeting with Norrecco in Copenhagen Denmark

Positive signals from meeting with Norrecco. The dialogue is now entering the next phase of setting up SWESTEP Installations in Denmark.

Norrecco’s interest lies in strengthening its positioning in the Danish Recycling Market, through the ability to offer a more sustainable and viable alternative, especially in the field of plastic recycling.

The first step is to look at setting up a SWESTEP Plant in Copenhagen Harbor.

Karl Magnus Mattsson – SWESTEP

Søren Eriksen – Norrecco

Martin Porsgaard – NISA

Karsten Ludvigsen – Norrecco

Trash to cash: How SWESTEP gives plastic waste a new life

People all over the world are throwing out large quantities of plastic each year, representing a huge sustainability issue. SWESTEP aims to address this by converting household plastic waste into sustainable oil and new plastic raw materials.

Over the past year, the Swedish green tech company has been working closely with Climate-KIC and the City of Copenhagen to carry out a feasibility study on the conversion of plastic waste to new sustainable oil. Since being established in 2012, SWESTEP has been developing an industrial process capable of turning all hydrocarbon-based waste and residues, such as plastic, into renewable fractions. In practical terms, this means that any organic waste stream can be considered as a feedstock, and duly be transformed into a wide range of renewable fuels or useful sustainable liquids and materials to be used again.

In theory, this process could have huge implications for how we deal with plastics, as well as waste management in general, as it could lead to the establishment of major circular economy loops into a city’s ecosystem, provide new sources of renewable energy, and create new revenues and jobs—effectively converting what was previously considered waste into a resource. One key aspect of SWESTEP’s technology is that the feedstock doesn’t require separating prior to processing, meaning mixed waste streams are just as effectively processed as sorted ones. This contrasts wildly with the status quo, in which mixed waste streams require appropriately sorting before the separate elements can be recycled.

Creating industrial inputs from waste plastic for industries that typically require fossil-based fuels or petrochemicals for major parts of their operations doesn’t just represent a welcome remedy to the problem of municipal waste, it also embodies potential to reduce the consumption of fossil-fuels and thus, contributes to climate change mitigation.

Given what was on offer, it’s easy to understand why Copenhagen was interested in a potential collaboration. Per Boesgaard, coordinator of the city’s Climate Plan 2025, had this to say:

“Waste management, and particularly plastic waste management, has represented a huge problem for the city for a long time. Plastic is now a large part of people’s daily lives, yet it represents a huge environmental problem with regards to both the consequences of its disposal and its carbon footprint.

Our challenge [as the City of Copenhagen] is to manage this problem holistically, which means solving the environmental issues without disrupting the day-to-day of our citizens. Thus, participating in projects such as this and collaborating with pioneering companies like SWESTEP to investigate the potential of their technology is both necessary and exciting for us as a city. We are very pleased with the outcome of this project and look forward to working more with SWESTEP and Climate-KIC in the future”.

Source DAILY PLANET; Read the full article – click here

Lastbil

NEWS FROM – MARKET

Axfood in Sweden takes its climate responsibility and stops choosing to fuel their trucks with HVO.

Åsa Domeij Sustainability Manager / Axfood says;

Now we stop to refuel our trucks with HVO, it contains palm oil and large-scale production of the risks driving the deforestation of the rainforest. Instead, Axfood calls for actions that promote the production of sustainable biofuels.

SWESTEP welcomes this decision, and hopes that more companies in Sweden will follow and choose renewable fuels that will not affect the natural balance of nature’s fauna. We recommend to look at WTL (Waste To Liquid) or WTE (Waste To Energy) as an alternative. Organic waste, incl. plastics is the future green raw material to produce renewable fuels that is viable in the coming CO2 Neutral Economy.

Source MARKET – Read the full article (in Swedish) – click here

Environment and Energy Fund Denmark – Support validation of Swestep’s process

Copenhagen politicians, just over three years ago, adopted a plan to start kick the recycling of the capital’s waste and limit the incineration. The plan meant that 45 per cent of household waste would be recycled in 2018, against 27 per cent in 2010. According to an evaluation made by the municipal officials January 2016, the goal could be achieved if one could find suitable technology that could produce renewable fuel/gas and fertilizers of industrial and household waste.

The municipality of Copenhagen is interested in testing the SWESTEP patented CC Process (Catalytic Conversion Process), which is a “Liquefaction Technology”. SWESTEP’s technology can offer sustainable renewable fuel and oil production by converting all forms of hydro carbon based waste and residues to renewable materials, such as synthesis fuels, chemicals, oils and polymers.

The purpose of this project is to validate results from SWESTEP’s technology. The goal is a more cost-effective, climate-friendly and sustainable way of using plastic waste for the production of renewable fuels.