The SWESTEP plant is scalable and flexible with regard to both the input material (feedstock) and end product perspectives.

Scalability with options with regard to size and number of production lines possible within each plant opens up the market for both small and large operators.

The product portfolio consists of the following production facilities;

- SWTP-500 (4 ML / Year)

- SWTP-1000 (8 ML / Year)

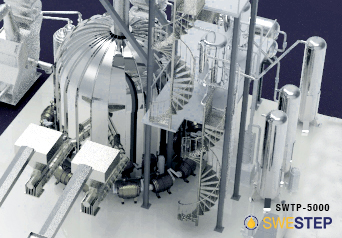

- SWTP-5000 (40 ML / Year)

In order to maximize the output of each SWESTEP Plant it is possible to combine different size SWPT units (production lines) to meet the desired production volume.

At the moment Swestep are doing research for a "Swestep Mobile Unit", and development are also conducted for the feasibility of a large scale plant with production capacity of 12,500 l/hr, which can then be easily scaled up to 25,000 l/hr. Larger plants are tailored and built based on the customers’ needs and requirements.