Swestep acquires new patents that will revolutionize production of fossil-free fuels

Swestep announces that they have acquired four patents for technology that will revolutionize the production of fossil-free fuels.

These four patents enables a more efficient production of renewable fuels from waste from paper and biomass and other organic waste including plastics, using Swestep’s CC technology.

– Swestep’s technology and the patents we have acquired mean that it is now possible to extract more renewable energy from waste from the paper and pulp industry than before. In addition, the investment cost is a fraction compared to what alternatives in the market require. This is an unbeatable combination, fully in line with what we have previously offered to handle other organic waste and plastics for other fossil-dependent industries globally, ”says Karl-Magnus Mattsson, CEO and founder of Swestep.

The basic function of CC technology is to convert organic waste, such as lignin, into a liquid end product which can be used directly as fuel or chemical raw material to refine into performance chemicals for the production of plastic, textile, glue or cosmetics. The oil can also be used as raw material for further processing – for example in the form of hydrogenation / additives to conventional diesel.

Through the process combinations that the patent covers, an efficient production of renewable fuels is obtained from primarily wood raw materials, including related waste such as lignin. The tests conducted with lignin show high cost efficiency.

– The Swestep process produces a liter of diesel from three kilos of lignin and biomass. It blends into one third each of non-recyclable plastics and cardboard products, which otherwise are burned up, with the biomass we get 1 liter of diesel from about 2.5 kg of waste, says Karl-Magnus Mattsson.

The first deliveries of customer facilities are expected to be up and running in 2020. Two of these plants are planned to be built in Sweden.

Link to original artikel in swedish

_____________

The SWESTEP process technology can effectively recycle all hydrocarbon-based waste, including plastic, into renewable additives and fuels for Air-Land-Sea or a virgin sustainable raw oil to refine into liquids or performance chemicals for the petrochemical industry. (Raw materials/liquids that can help fossil dependent industries close the loop for future production of textile, cosmetic, medicine and plastic)

Plastic is Fantastic…

If made Circular and Sustainable with clear rules, laws and requirements about where/how it must be recycled

Today, most of all plastic waste goes to incineration and only a minor part is mechanically recycled. In addition, mechanical material recycling gives plastics a lower quality than the original.

Therefore, it is important to highlight feedstock recycling as a justifiable and profitable alternative for industry to produce green plastic products with guaranteed quality that meet the sustainability and environmental requirements.

Swestep’s CC Process is an efficient method for plastic recycling, the waste can be broken down at molecular level and deliver an oil product that can be refined into performance chemicals and/or new optional plastic products that meets the industry quality requirements.

– Another advantage of Swestep’s technology is that it also allows a gradual phase-out of fossil dependence.

Plastic waste recycling is poised to be the most important and transformative trend in the petrochemicals industry during the coming decade. Replacing plastic with other materials is not practical. When considering all aspects of the product lifecycle, plastics have a much lower environmental cost than their alternative materials.

So, while opportunities exist to reduce per capita plastic consumption, the solution to plastic waste must include the ongoing use of plastics for their superior material properties.

The end products are renewable fuels, energy and/or a chemical raw material (in liquid form) that can be processed into performance chemicals and new materials for all fossil-dependent industries.

Important to emphasize is that Swestep’s patented CC process (Catalytic Conversion Process) mimic natures decay process, but in contrast to that it takes nature millions of years Swestep’s solution do it under 6 minutes.

The technology is a combined feedstock-, chemical-, and mechanical recycling process that can recycle all hydrocarbon-based waste and residues. (Including contaminated waste, end of life products and flame retardant material)

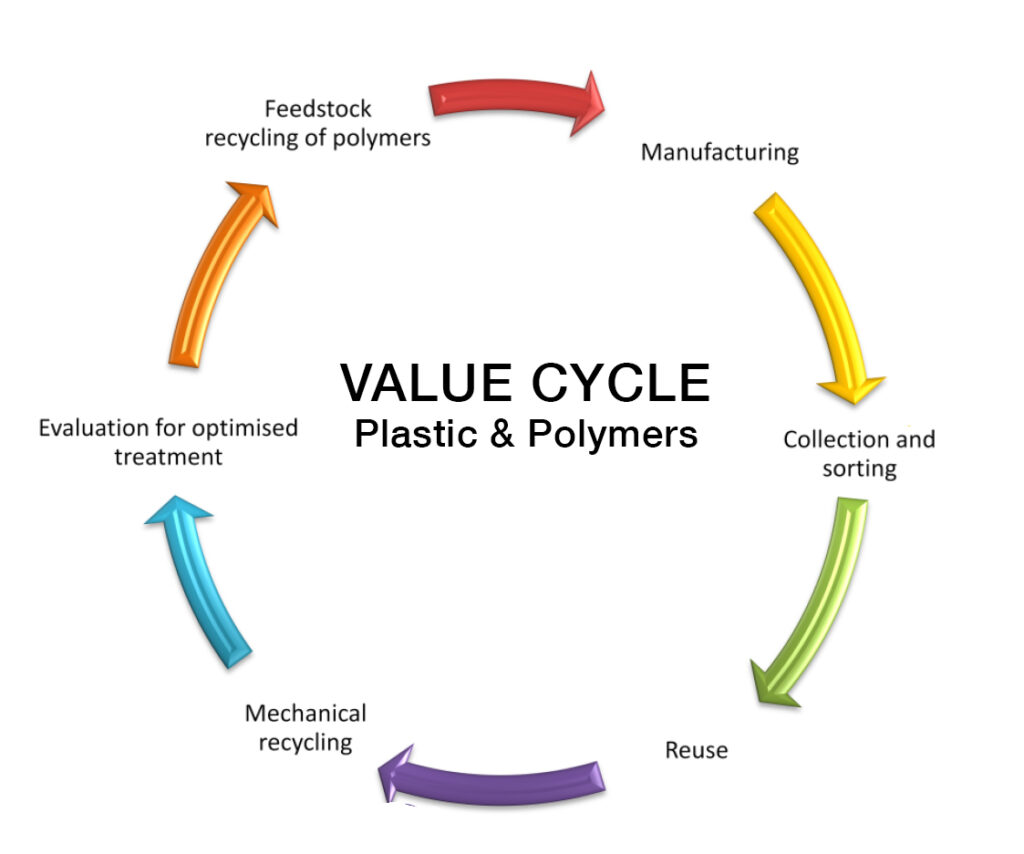

Priority is given to circularity, and therefore it is graded in the following order;

1. Reuse, 2. Mechanical Recycling, 3. Feedstock Recycling. However, all solutions have their pros and cons. – Quality requirements, handling, sorting, cost, time, profitability and environmental impact.

INFORMATION – The CC process is NOT an incineration technology – There are no chimneys; Thanks to that the production process runs under 300°C there are no cancerogenic (Furans, dioxins…) emissions produced.

Time to take the next step

Time for change

Swestep – All residues come to use

Plastic in our environment and food

Microplastics come from many sources: synthetic clothing fibres, dust from tyres, road paints, and the breakdown of larger items. Orb Media’s recent investigation has brought the issue of microplastics in the environment into sharp focus. The analysis of tap water samples from around the world found that a high proportion of drinking water is contaminated with microscopic fragments of plastic (83% of samples collected worldwide, but up to 94% in the USA). Microplastic contamination seems more widespread than we perhaps knew, and they are regularly being ingested by people worldwide. Most concerning is how little is known about the effects of microplastic consumption on human health.It is no small problem.

As of 2015, 6300 million tonnes of plastic waste have been generated, around 9% of which was recycled, 12% was incinerated, and 79% ended up in landfills or the environment. The issue of large plastic items polluting the world’s oceans is well known, leading to policies that aim to limit the production and use of plastic bags and bottles, and increase recycling. However, a key problem with plastics is that they are essentially indestructible; rather than being biodegraded, they break down into smaller and smaller pieces, eventually becoming microscopic fragments.

We should no longer just be concerned with large plastic items clogging up oceans and waterways, but also more attention needs to be paid to these tiny fragments and their effects on planetary health.

Prince Charles stated at a recent Our Ocean summit,

“Plastic is very much on the menu”.

Health – How plastic affects us

Humans are already eating plastic from the sea. The average person who eats seafood swallows up to 11,000 pieces of microplastic every year, according to a study by researchers at the University of Ghent. Most concerning is how little is known about the effects of microplastic consumption on human health (Microplastics and human health—an urgent problem, The Lancet, 2017)

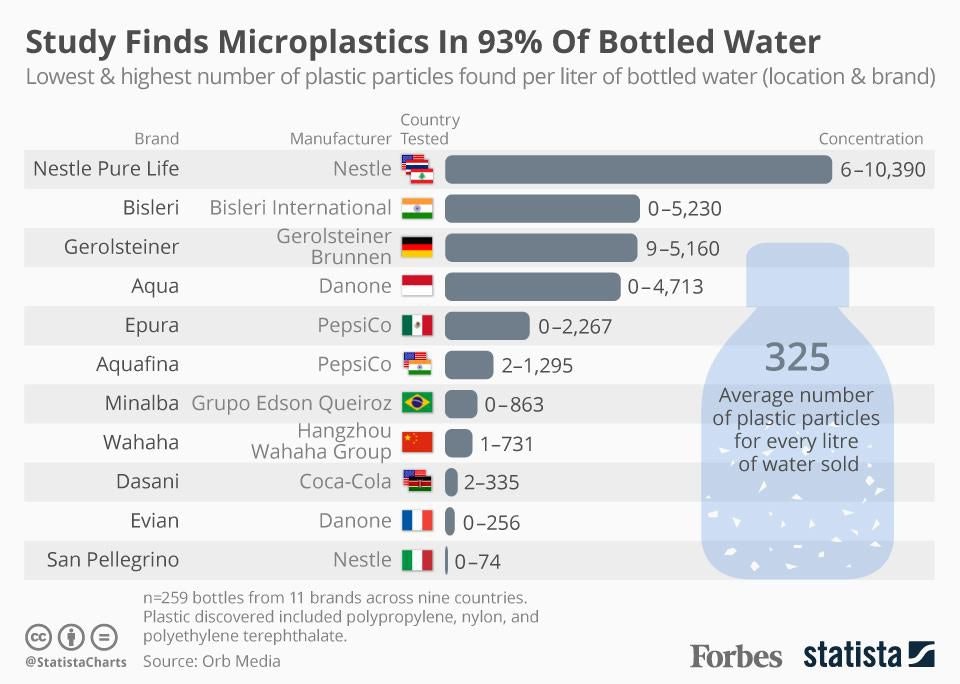

In March 2018, the World Health Organisation announced a review into the potential risks of plastic in drinking water after an analysis found 90% of some of the world’s most popular bottled water brands contained tiny pieces of plastic. A previous study also found high levels of microplastics in tap water.

First, the amount of plastic being released into the environment must be drastically reduced. Some policies have already been formulated with this goal in mind, for example, many countries have made it illegal for retailers to give away plastic bags for free, and deposit schemes for plastic bottles are in place in parts of the USA and Europe. However, progress on this front has been slow and piecemeal.

“The research unveils the need for companies to consider their plastic footprint, just as they do for carbon, water and forestry,” said Andrew Russell, Director of the PDP. “By measuring, managing and reporting plastic use and disposal, companies can mitigate the risks, maximize the opportunities, and become more successful and sustainable.”

Time to take the next step

Time fore change

#Swestep – All residues come to use

SOURCE: The Lancet – Planetary Health

Swestep is invited to talk about our CC (Catalytic Conversion Process) recycling technology on October 24 in Lund.

The Advanced Materials Day will be an event focusing entirely on innovative and sustainable materials for international investors as well as local materials professionals from industry and academia.

Lund is quickly becoming an interesting hub for materials research, especially now that the MAX IV facility offers the highest quality of X-rays available to scientists from academia and industry worldwide. So nowhere better to host an event focusing on materials than there! Around 100 materials experts, researchers, innovators and investors will have the chance to exchange knowledge and contacts for a whole day.

Swestep have great expectations on this day, see this link about the event.

Positive results on initial tests on green aviation fuel

– Opens up for a cost-effective large-scale production

SWESTEP has successfully completed early tests to convert organic waste into non-fossil, green renewable diesel and aviation fuel. The process, which is patented, means that the production cost per liter of green fuel is very attractive.

SWESTEP offers an innovative technology for producing green fuel through its unique CC process (Catalytic Conversion) where organic waste as household waste, incl. plastics, tires and biomass (residues from farming and forestry including wood and demolition wood) are converted into synthetic non-fossil diesel and kerosene (aviation fuel).

“Preliminary study results indicate that the production cost of SWESTEP’s non-fossil fuels is in line with fossil diesel and fossil aviation fuel, which is a major achievement. Our technology for producing non-fossil fuel is more cost-effective and more flexible than the alternatives, which opens up enormous opportunities.” Says Karl-Magnus Mattsson, CEO and founder of SWESTEP,

Climate Kic together with the City of Copenhagen and Kastrup Airport have participated in a study where waste has been tested and fuel is produced, with good results. Further tests and refinement of the process will be carried out in SWESTEP’s planned Facility (R&D + Test + Producton) in Ljungby, Sweden.

Tech.Dr. Anders Östman at “Scandinavian Chemistry Information” has participated in studies where various mixtures of residual products / waste as input material have been tested and notes that the results are promising. The tests performed on a smaller scale show positive results.

SWESTEP’s process is CO2-neutral, renewable and fossil-free and the feedstock can consist of, for example, biomass-based waste. SWESTEP’s manufacturing process takes place at low temperatures and no harmful emissions of, for example, furan or dioxin occur.

“It is a climate-smart, simple and storable solution with good economy. This means new opportunities for local self-sufficiency, while at the same time it is easy and cost-effective to scale up production for those who want to carry out larger industrial production,” says Karl-Magnus Mattsson.

“In the future, aviation fuel produced by SWESTEP technology will undergo formal tests for type approval and certification. We expect an approval because it is of a very high quality. And add that it is non-fossil product, gives us great expectation due to the industries market demand”. He concludes.

Link to original artikel (Dagens Infrastruktur) in swedish

________________________________________________________________________________________________

SWESTEP – “The Next Generation Process Technology for Sustainable Recycling Production” –

SWESTEP develops and sells SWESTEP-Plants. The technology can recycle all types of hydrocarbon-based residues and waste, including plastics, into renewable energy and fuels (for Air-Land-Sea) green raw oil or liquid to refine into performance chemicals, for the petrochemical industry. (New green raw material that can help fossil-dependent industry to “Close the Loop”, plastics, textiles, cosmetics, construction, etc.)

SWESTEP’s technology copies nature’s decomposition process, which converts organic residues and waste into renewable oils, minerals and and performance chemicals. But with the great difference that SWESTEP’s technology takes less than 6 minutes instead of the more than 100 million years it takes for mother earth.

SWESTEP’s technology involves a cost-effective extraction of renewable energy such as fossil-free oil, renewable diesel and green aviation fuel from residual products in our local environment, which partly facilitates waste management and self-sufficiency in energy, and partly leads to significant emission reductions compared to extraction of fossil oil taken up from the ground, Refined with associated emissions and then transported long distances over the soil before it is used (which in total means greater greenhouse gas emission.

SWESTEP has been nominated for – The Nordic Counsel Environmental Prize -, by Climate KIC in Denmark. This is the result of established partnerships with, among others, City of Copenhagen, Kastrup Airport, NISA (Nordic Initiative for Sustainable Aviation), KTH, Lund University and DTU (Technical University of Denmark).

SWESTEP and CLIMATE KIC are now on the OID Tour in India – “The Open Innovation Day”

The Government of India has launched a bold, the Smart Cities Mission Initiative.The program aims to establish frameworks that can be replicated both within and outside the Smart Cities Mission alliance, catalysing the creation of similar smart cities in various regions and parts of the country.

In order to provide concrete solutions to this problem, Climate KIC together with partners tasked by Nordic Innovation to identify innovative solutions though Open Innovation Day (OID).

The Government of India welcomed the concept to utilize “OID” for the purpose of tackling the water and waste challenges of urban sustainability. The Open Innovation Day target the following cities: Mumbai, Panaji, New Delhi, Shimla.

Each of the cities selected, offer specific and unique qualities as an innovation ecosystem. And in the same time each city faces significant environmental challenges – often associated with a metropolis –which again despite having a common theme, vary significantly between settlements.

The Indian Central Government has committed INR 480 billion (equivalent to €6 Billion) in order to finance the mission, a figure that is conditional to equal funding from the state governments.

– “SWESTEP is a waste to energy company among 9 companies that was selected by Climate Kic. We see our Swestep Plants as a natural choice since we offer one solution to two problems, an economically and environmentally viable solution that addresses the waste and water problems at the same time”. Says Karl-Magnus Mattsson, CEO and founder of SWESTEP, and continues. “Our sustainable process technology can effectively recycle all hydrocarbon-based waste, including plastic, into renewable additives and fuels for Air-Land-Sea or a virgin sustainable raw oil to refine into liquids or performance chemicals for the petrochemical industry. Raw materials that can help fossil dependent industries close the loop for future production of textile, cosmetic, medicine and plastic” –.

India is yet to unlock the full growth potential of its urbanisation process, and the existing urban infrastructure is not equipped to accommodate the coming dramatic growth of its cities.

Peter Vangsbo, Nordic Business Developer, EIT Climate Kic, says, – “Given the scope of this project and scale of environmental challenges within each city, not just in terms of magnitude of the problem but also number of people affected. We consider that the challenges require world-class solutions which OID has the potential to deliver through support from the Climate KiC global presence and networks” –.

– “The first days here in India, on the Open Innovation Day Tour, have been fruitful, inspiring and constructive. We look favorably on the broad interest we get, –. Says Karl-Magnus Mattsson and ends with”. When we see the problems and challenges, we feel a responsibility to act now and deliver an economically and environmentally defensible solution that is viable to everyone and everything” –.

Link to the Open Innovation Day (OID) Initiative

SWESTEP EIT – CLIMATE KIC

Karl-Magnus Mattsson – CEO & Founder Peter Vangsbo – Nordic Business Developer

Phone: +46 (0) 763 97 9574 Phone: +45 (0) 123123123123

Mail: kmm@swestep.com Mail: peter.vangsbo@climate-kic.org

SWESTEP was invited to VESTFORBRÆNDING in Copenhagen to talk about plastic waste

SWESTEP see plastic waste as a valuable feedstock that can be processed into sustainable fuels and energy, or also as a chemical raw materials to refine into performing chemicals for the fossil-dependent industry.

CEO Karl Magnus Mattsson’s speech on how SWESTEP’s Catalytic Conversion technology recycles plastic waste in an both economic and environmental viable way led to many questions and interesting dialogues.

VESTFORBRÆNDING is Denmark’s largest waste management company.

Each year VESTFORBRÆNDING handle around 1 million tonnes of waste and the focus is on the resource value of the waste – whether it is materials for recycling or fuel for energy production.

SWESTEP sees this as a interesting and rewarding first step and looks forward to the next step.

Picture above – Some of the participants from the meeting;

Henric Jacobsen – VESTFORBRÆNDING

Nana Winkler – DANSK AVFALDSFORENING

Martin Porsgaard – NISA (Nordic Initiative for Sustainable Aviation)

Anders Kiil – VESTFORBRÆNDING