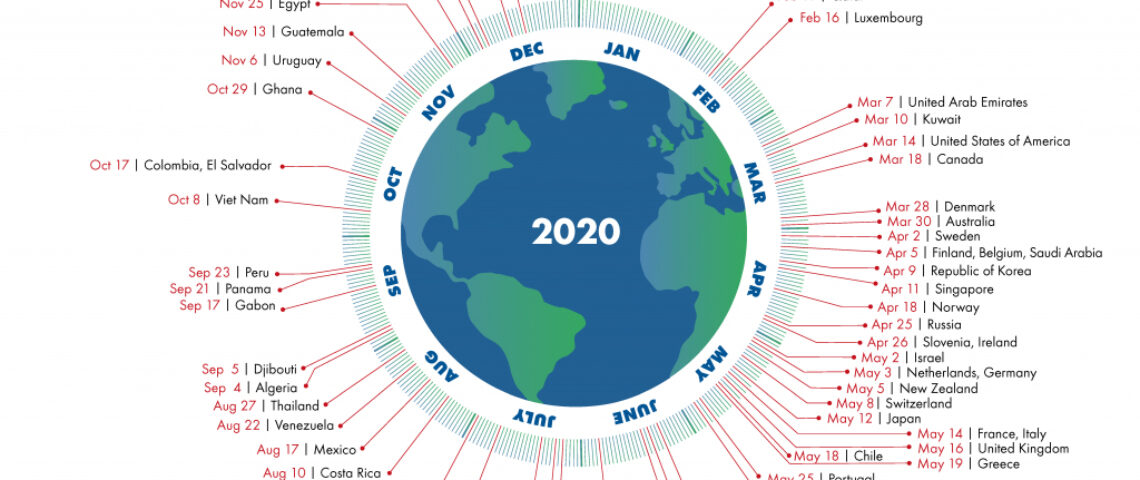

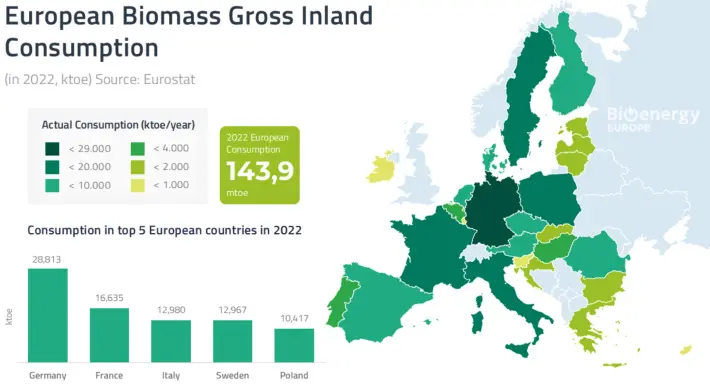

This is the view of Bioenergy Europe, which in early 2025 released its Bioenergy Landscape Report 2024, a detailed analysis of the role of bioenergy in supporting Europe’s transition to a net-zero emissions economy by 2050. The report delivers important insights for decision-makers and market participants and highlights bioenergy’s contribution to reducing climate impact, increasing energy security and economic competitiveness.

Source: Bioenergy

The 2024 Landscape Report provides clear and useful data to understand the role of bioenergy in Europe’s work to reduce climate impact, says Jean-Marc Jossart, Secretary General of Bioenergy Europe, and continues:

Bioenergy is still the largest renewable energy source in Europe today and offers unprecedented opportunities to reduce emissions, create jobs and strengthen energy security by using local resources.

Engine of growth and innovation

The report shows that bioenergy accounted for 54 percent of Europe’s renewable energy mix in 2022, avoiding 300 million tonnes of fossil carbon dioxide emissions annually. The sector contributes directly to Europe’s energy security by reducing its dependence on energy imports while boosting rural economies and providing local jobs.

“Europe has a unique opportunity to lead the way in renewable technologies, creating 1.5 million jobs and potentially increasing EU GDP by up to €70 billion by 2050. It is time to put bioenergy at the heart of Europe’s energy, industrial and climate strategies,” adds Jossart.

Bioenergy Europe’s recommendations:

Bioenergy Europe identifies four critical areas where bioenergy can deliver immediate and long-term benefits to the EU’s climate and energy goals and unlock the full potential of bioenergy as a cornerstone of a net-zero economy:

1. Stimulate bio-based carbon capture technologies

The EU should encourage bio-based carbon capture technologies such as BECCS (Bioenergy with Carbon Capture and Storage) to achieve European low-carbon targets and support the industrial transition from a fossil-based to a bio-based economy.

2. Accelerate the upgrade of sustainable heating equipment

Modern bio-heating equipment offers a cost-effective solution to reduce fossil emissions in the EU’s heating sector. Replacing older equipment with modern solutions will improve energy efficiency, reduce emissions and lower costs for both households and businesses.

3. Secure a sustainable supply of biomass

A secure and sustainable supply of biomass will strengthen Europe’s bio-economy and support its energy and climate goals. The bioeconomy strategy should reflect this.

4. Ensuring stable regulatory frameworks

Stable regulatory frameworks are crucial to attracting investment and fostering innovation. This is important to increase the EU’s competitiveness and drive the transition to a net-zero economy.

Source: Bioenergy (Swedish)

Time for change – Time to take the next step

The waste management sector faces an urgent need for adaptation as the demand for change becomes increasingly urgent. It is now clear that the establishment of a comprehensive waste lifecycle management system, combined with a methodical approach to promoting a circular economy, is imperative.

The concept of a circular economy revolves around the ambition to eliminate waste and environmental pollution, extend the usefulness of products and materials or recreate natural ecosystems where waste is turned into value in a circular perspective. A recent report from the United Nations Development Program (UNDP) outlines various initiatives that focus on the management of residues and waste, all with the common aim of promoting the principles of circularity.

one of the potential solutions is closer at hand than you might imagine. SWESTEP offers an environmentally sustainable recycling solution that is not only in line with ecological goals but is also economically viable.

source – UN

Link to access the full UN Report

Giving plastic waste a new life

People all over the world are throwing out large quantities of plastic each year, representing a huge sustainability issue.

Over the past year, the Swedish green tech company has been working closely with EIT Climate-KIC and the City of Copenhagen to carry out a feasibility study on the conversion of plastic waste to new sustainable oil. Since being established in 2012, SWESTEP has been developing an industrial process capable of turning all hydrocarbon-based waste and residues, such as plastic, into renewable fractions. In practical terms, this means that any organic waste stream can be considered as a feedstock, and duly be transformed into a wide range of renewable fuels or useful sustainable liquids and materials to be used again.

In theory, this process could have huge implications for how we deal with plastics, as well as waste management in general, as it could lead to the establishment of major circular economy loops into a city’s ecosystem, provide new sources of renewable energy, and create new revenues and jobs—effectively converting what was previously considered waste into a resource. One key aspect of SWESTEP’s technology is that the feedstock doesn’t require separating prior to processing, meaning mixed waste streams are just as effectively processed as sorted ones. This contrasts wildly with the status quo, in which mixed waste streams require appropriately sorting before the separate elements can be recycled.

Creating industrial inputs from waste plastic for industries that typically require fossil-based fuels or petrochemicals for major parts of their operations doesn’t just represent a welcome remedy to the problem of municipal waste, it also embodies potential to reduce the consumption of fossil-fuels and thus, contributes to climate change mitigation.

Given what was on offer, it’s easy to understand why Copenhagen was interested in a potential collaboration. Per Boesgaard, coordinator of the city’s Climate Plan 2025, had this to say:

‘Waste management, and particularly plastic waste management, has represented a huge problem for the city for a long time. Plastic is now a large part of people’s daily lives, yet it represents a huge environmental problem with regards to both the consequences of its disposal and its carbon footprint.

Our challenge [as the City of Copenhagen] is to manage this problem holistically, which means solving the environmental issues without disrupting the day-to-day of our citizens. Thus, participating in projects such as this and collaborating with pioneering companies like SWESTEP to investigate the potential of their technology is both necessary and exciting for us as a city. We are very pleased with the outcome of this project and look forward to working more with SWESTEP and Climate-KIC in the future.’

In July 2016, the City of Copenhagen, SWESTEP, NISA, Copenhagen Airports, and other partners, took part in “Trash to Cash” an EIT Climate-KIC Pathfinder project aiming to confirm if their “turnkey technology” can make a positive impact to the city’s plastic waste challenge. After testing the process on a batch composed of plastic and biomass, the feasibility study confirmed that both the feedstock, the technology, and the process were viable. Karl-Magnus, CEO of SWESTEP, had this to say about the process:

‘I am delighted with the results because we can now show that SWESTEP can use our process to recycle a mixed organic MSW feedstock that includes plastics. We already are planning for further tests on other special feedstocks to evaluate their economic potential.

The outputs of the process can be used as an environmentally sound substitute for fossil fuels and thus, the municipality waste can end up being recycled into a whole range of things, such as new textiles, new plastics, medicines, renewable diesel, and jet-fuel. I am also proud that we have proved we can make a difference in waste management processes whilst also being an asset to the energy sector. Through our process, we can create new jobs, new industries, and new revenue streams for the city municipalities—all in an environmentally and climate-friendly way.’

Martin Poesgaard, Director of NISA, the Nordic Initiative for Sustainable Aviation is optimistic about the process: ‘With the results of this feasibility study we can see that it is possible to convert the waste plastic residues to a new oil. We [at NISA] find it quite remarkable as it occurs at relatively low temperature and without pressure setting. Our hope is that the oil produced can be further processed into a sustainable jet fuel as if possible, this could represent a major breakthrough in our efforts to make the aviation industry more sustainable.’

SWESTEP will now proceed with additional documentation and analysis of the technology and the end products. Now, the goal is to find industrial partners and investors as well as involvement from the public and the government. SWESTEP is very optimistic about this and sees the solution as an important and low-cost contribution to the circular economy and environmental improvements.

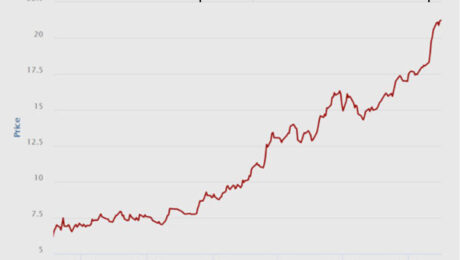

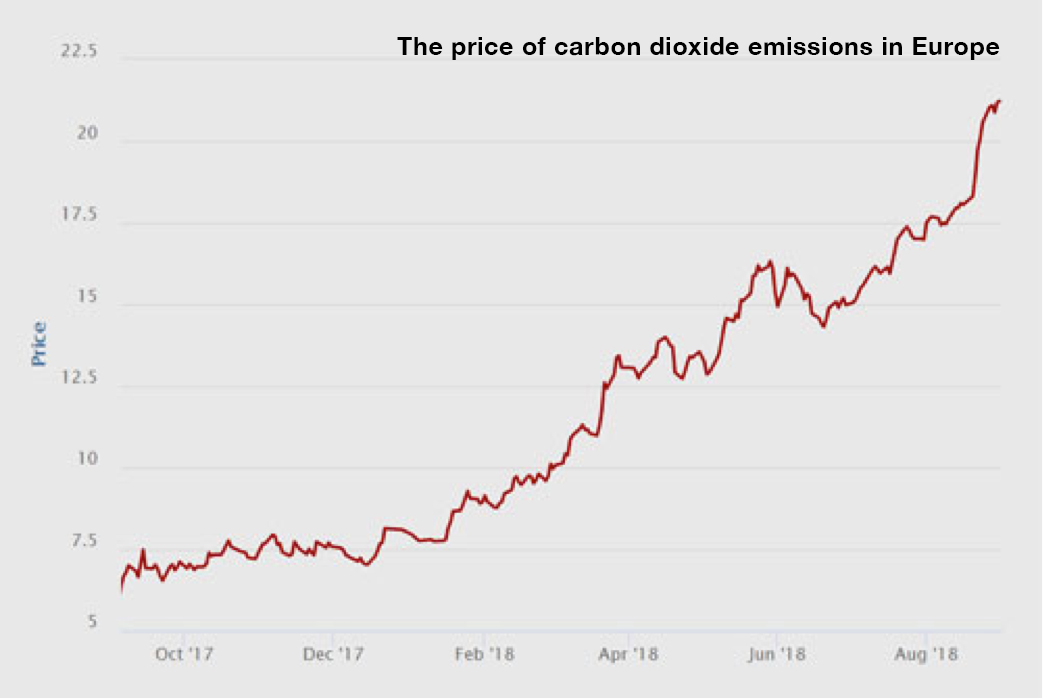

The price of emission allowances for carbon dioxide rises to the skies

In August, the price of emission allowances has risen to over 21 dollars per ton, the highest level of a decade.

The EU Emissions Trading Scheme is an instrument for cost-effective reduction of greenhouse gas emissions. The system is based on common EU rules, covering all member states and Norway, Iceland and Liechtenstein. EU emissions trading began in 2005. Since its inception, the system has been expanded step by step and now applies to more industries.

Today, some 13,000 European facilities are included in the system, of which about 750 are in Sweden. Many facilities are located in energy-intensive industry and energy production.

The trading system has received a lot of criticism over the years but now it seems that Europe finally got it.

During the third week of August, the price of emission rights to over 20 dollars per ton, the highest level in a decade.

But not only that. Costs to generate electricity from both coal and gas have also risen sharply since the beginning of 2017, not least because the price of imported coal and gas has risen.

The cost of generating electricity from coal has risen by 72 percent to 46 euros per MWh and the equivalent for gas is 43 percent to 49 euros per MWh.

An analysis by Berenberg Bank argues that the shortage of allowances will be able to drive the price up to 100 euros per ton by 2020.

Source / Link – Veckans Affärer (Article in Swedish)

Wasted Health: Pollution is Killing Millions

Two years after ISWA’s Report “Wasted Health: The tragic case of dumpsites” that described the linkages between the world’s dumpsites and human health, a new landmark report that was published recently by the Lancet Commission on Pollution and Health reveals that pollution kills at least nine million people and costs trillions of dollars every year. This report stems from the most comprehensive global analysis to date,

and warns the crisis “threatens the continuing survival of human societies”.

A comparison of the two reports reveals important common conclusions and concepts, highlighting that the health impacts of pollution, as well as the health impacts of dumpsites, remain rather underestimated.

Both reports concluded that the assessed health impacts are probably the minimum ones that can be estimated with very conservative assumptions.

Parallels Between Lancet Commission on pollution and health and ISWA’s Wasted Health

The new report estimates that diseases caused by pollution were responsible for an estimated 9 million premature deaths in 2015—16% of all deaths worldwide — a staggering number and three times more deaths than from AIDS, tuberculosis, and malaria combined and 15 times more than from all wars and other forms of violence. In the most severely affected countries, pollution-related disease is responsible for more than one death in four…

Source ISWA NEWS; Read the full article – click here

Lastbil

NEWS FROM – MARKET

Axfood in Sweden takes its climate responsibility and stops choosing to fuel their trucks with HVO.

Åsa Domeij Sustainability Manager / Axfood says;

Now we stop to refuel our trucks with HVO, it contains palm oil and large-scale production of the risks driving the deforestation of the rainforest. Instead, Axfood calls for actions that promote the production of sustainable biofuels.

SWESTEP welcomes this decision, and hopes that more companies in Sweden will follow and choose renewable fuels that will not affect the natural balance of nature’s fauna. We recommend to look at WTL (Waste To Liquid) or WTE (Waste To Energy) as an alternative. Organic waste, incl. plastics is the future green raw material to produce renewable fuels that is viable in the coming CO2 Neutral Economy.

Source MARKET – Read the full article (in Swedish) – click here

European countries spend billions a year on fossil fuel subsidies, survey shows

Governments of 11 European nations are providing subsidies totalling more than £80bn a year to fossil fuel industries, green campaigners have claimed.

Transport fuels account for the lion’s share of the support to fossil fuels. Many of the 11 countries surveyed encourage drivers to use diesel as it produces less carbon per mile than petrol, despite the fuel’s effects on air pollution which is particularly harmful to children. For many years, governments had incentives to prioritise the use of diesel, as it helped them meet internationally-set carbon reduction targets.

A substantial amount of the claimed subsidies are for fuels such as gas, which is viewed by many as a transition away from more carbon-intensive fuels such as coal.

Taxpayer support for electric vehicles, renewable electricity and other low-carbon efforts were not counted in the study by the Overseas Development Institute (ODI).

In the UK, diesel fuel is taxed by volume at the same rate as petrol. This taxation can favour the dirtier fuel because diesel cars travel further than petrol vehicles on the same volume of fuel.

Half of the support provided to fossil fuels was targeted at low-income households, the report acknowledged. Such measures by governments are intended to protect people on low incomes from fuel poverty. Nearly €5bn of the overall support was provided in this way by the UK government alone.

Shelagh Whitley, head of climate and energy at the ODI, said: “The air pollution crisis in cities across Europe and the recent diesel emissions testing scandal have rightly led to increased pressure for governments to act [on air quality]. Yet our analysis shows European countries are providing enormous fossil fuel subsidies to the transport sector.”

“This study shows how governments in Europe and the EU continue to subsidies and finance a reliance on oil, gas and coal, fuelling dangerous climate change and air pollution with taxpayers’ money.”

Source – The Guardian Read the full article – click here

Stop exporting plastic waste to China to boost recycling at home, say experts

Governments must end incentives that see plastic waste shipped abroad, where it may be buried or burned, rather than being turned back into bottles at home, say industry leaders

Governments must stop exporting so much plastic waste to countries such as China and keep more in-country to be recycled into bottles to tackle the waste crisis, industry insiders say.

A day after the Guardian revealed that a million plastic bottles are bought every minute across the world, experts aiming to provide a closed loop in which each bottle is used to make a new one, say their industry faces multiple hurdles.

Chris Brown of Clean Tech, based in Lincolnshire – the only site in the UK which produces food grade recycled polyethylene terephthalate (Pet) from plastic bottles to turn them into new bottles – said: “It has been a very challenging environment.”

“The recycling of Pet back into rPet (recycled plastic) is a relatively new industry and it has proven very difficult for any businesses to survive in recycled plastics. The margins are such that they struggle to be successful, particularly when the processes require large capital investment and present a significant technological challenge.”

He called for the UK government to end the incentives for export of post consumer plastic to China and other countries – more than two-thirds of plastic collected for recycling in the UK was sold abroad in 2016, where it may be incinerated or buried rather than recycled according to industry experts quoted by Greenpeace.

“Being able to keep more of that material in this country would be better for the bottle manufacturers and their customers,” he said. “It is important that the feedstock is available for rPet producers, so what we would like to see is an end to the incentivising of its export. Having an incentive to export the bales instead of keeping them in the country to be used to make more plastic bottles does not seem like what we should be doing at the moment.”

NEWS from FORBES

Plant Waste Can Make Carbon Fiber Cheaper

The Flintstones aside, wood is not the first choice for car parts. But when blended into carbon fiber, it turns out that a wood byproduct could lower the cost of the high-tech material without sacrificing its strength.

Carbon fiber reinforced plastic is very light and very strong. The fibers are short chains of carbon atoms bundled together and twisted into long strands. Those can be woven together and locked inside an epoxy resin to make stiff, lightweight parts for jets, prosthetics, cars and more.

As with so many human inventions, plants beat us to it long ago. They evolved their own light and strong reinforcement for building structures: lignin. It’s a carbon-based biological polymer that gives strength and rigidity to plant cell walls and helps prevent rot. It typically makes up about between one-fifth and one-third of the dry mass of wood.

Lignin’s toughness and resilience makes it great for plants, but it’s generally a nuisance when it comes to wood and plant products. When wood or plants are broken down to pulp to make paper or ethanol, lignin is treated as a waste product. It’s either sent to a landfill or burned for energy, which isn’t much of an improvement. Now bioengineer Birgitte Ahring has come up with a better use for lignin.

Source – FORBES Read the full article – click here

- 1

- 2