Two-day seminar on Green Bonds in Gothenburg,

included workshops on green financing, the future

of green cities and, last but not least, new regulations

and opportunities.

Several interesting participants from municipalities,

companies, banks and financial institutions.

Both good new contacts and tangible results

through our participation in this workshop.

To be continued…

Fruitful and interesting day full of meetings with both the municipal

responsible Camilla Svensson – Head of Waste Technical Operations

at Stenungsund and Vice President Lars Lind – Bio Fuels from Perstorp.

We look forward to the next step in this dialogue on cooperation

between the municipality, the locally established Petrochemical

Industries and SWESTEP

To be continued…

SWESTEP invited to Copenhagen by CLEAN on

finding solutions for “Innovative plastic sorting

and reprocessing solution

Creative Director, JP Morgan Friberg gave a talk on SWESTEP’s

technology as well as a general picture of the difference between

– Reusing and Recycling plastic waste and residues – from a circular

economic perspective with focus on the product lifecycle and future

producer responsibility.

The challenge is that, through an announced, Danish international Tender,

come up with viable and profitable solutions throughout the value chain.

From collection and sorting to processing and recycling the plastic waste into renewable non-fossil end products and/or liquids

To be continued…

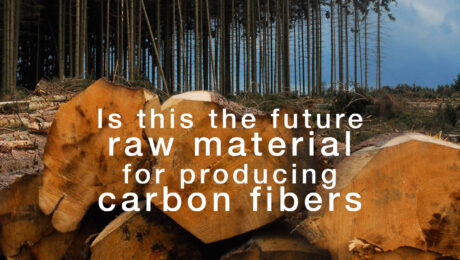

NEWS from FORBES

Plant Waste Can Make Carbon Fiber Cheaper

The Flintstones aside, wood is not the first choice for car parts. But when blended into carbon fiber, it turns out that a wood byproduct could lower the cost of the high-tech material without sacrificing its strength.

Carbon fiber reinforced plastic is very light and very strong. The fibers are short chains of carbon atoms bundled together and twisted into long strands. Those can be woven together and locked inside an epoxy resin to make stiff, lightweight parts for jets, prosthetics, cars and more.

As with so many human inventions, plants beat us to it long ago. They evolved their own light and strong reinforcement for building structures: lignin. It’s a carbon-based biological polymer that gives strength and rigidity to plant cell walls and helps prevent rot. It typically makes up about between one-fifth and one-third of the dry mass of wood.

Lignin’s toughness and resilience makes it great for plants, but it’s generally a nuisance when it comes to wood and plant products. When wood or plants are broken down to pulp to make paper or ethanol, lignin is treated as a waste product. It’s either sent to a landfill or burned for energy, which isn’t much of an improvement. Now bioengineer Birgitte Ahring has come up with a better use for lignin.

Source – FORBES Read the full article – click here